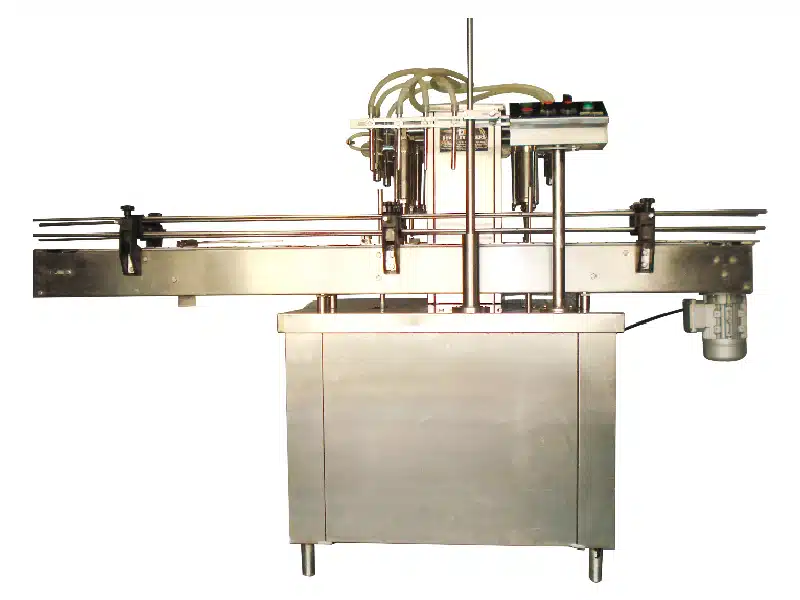

Operation

Bottles are feed on to in-built Infeed Turn Table, from where it delivered to SS conveyor belt. Conveyor belt transport Bottles to Filling Station. Filling station has Pneumatic bottle stopper for exact bottle neck centering of bottles during filling Operation. Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose. The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum use of time. After liquid filling bottles are delivered to capping/labeling machine conveyor for further operations.

Salient Features

- CGMP Model

- Rigid vibration free construction for trouble free performance.

- SS Elegantly matt-finished body.

- Elegant and easy control panel for total control on operation.

- Minimum change over time from one size to another container or fill size.

- User friendly Machine.

- Low maintenance cost.

- All contact parts made of S.S. 316.

- No Bottle No Filling System.

- Pneumatic Control Bottle Stopper.

- Filling Accuracy ± 1% in single dose (Depends upon fill size & nature of liquids).

- Machine provided with PLC (OPTIONAL) as per customer requirement.

Technical Specification

| Model | DLF-50 | DLF-100 | DLF-150 |

| No. of Heads | Two Heads | Four Heads | Six Heads |

| Output | 20-40 Bottles/Min | 40-80 Bottles/Min | 60-120 Bottles/Min |

| Input Specifications | Dia.: 30mm to 100mm Height: 210mm. Maximum Customized bottle height can be accommodated |

||

| Fill Range | 10 ml to 500 ml – in Single Dose with the help of change parts | ||

| Electrical | 1.5 HP, 440 Volt | 1.5 HP, 440 Volt | 2.0 HP, 440 Volt |

| Characteristics | 3 Phase, 4 Wire System | 3 Phase, 4 Wire System | 3 Phase, 4 Wire System |

| Overall Dimensions (LXWXH) | 1500 X 800 X 1500 | 1500 X 800 X 1500 | 1800 X 900 X 1500 |

| Conveyor Height | 800 mm 50 mm | – | – |