Dhara Engineers manufacture a range of Filling Machines, built for applications in toiletries, oils, inks, syrups, tomato ketchup, honey, etc. All our Filling Machines ensure precision, efficiency, and hygiene in the filling process as it is required by pharmaceuticals, food processing, cosmetics, and chemical industries. Built-in high-end technology and strong materials, our filling machines keep on performing optimally and ensuring compliance with international standards. Trust Dhara Engineers for innovative and reliable solutions to improve your production line.

Automatic Shampoo Filling Machine

Automatic Shampoo Filling Machine is a contemporary solution in the field of filling bottles, containers, and so on in personal care and cosmetics industry. This machine brings forth good ergonomic and productivity enhancement, avoiding manual error and filling shampoos into bottles and containers of different dimension sizes. Empowered with control technology of modern servos and PLCs, its efficiency rules not only for accurate volume dispense but also for smooth operation.

The machine is made of high-grade, stainless steel material to ensure hygiene and durability, complying with GMP and FDA standards. It can fill products from different viscosities, making it ideally suited not just for shampoos but for conditioners, lotiones, etc. Drip-proof nozzles, adjustable filling heads, and easy interface flexibility are some useful features for the use of small and large quantities of production. The Automatic Shampoo Filling Machine is a perfect embodiment of precision, speed, and reliability. Its user-friendly approach also decreases down time and maintenance costs yet remains constant in output. Thus, this specific machine becomes a useful addition to companies, be it small startups or larger conglomerates of manufacturers, in getting a greater degree of operational efficiency to meet demands from the market. Perfectly tailored for the requirement of business operations, the Automatic Shampoo Filling Machine improves thereby making it an investment worth considering by manufacturers. Optimize production with high performance for small business users or large scale production with this high-performance Automatic Shampoo Filling Machine!

Automatic Oil Filling Machine

It is a highly developed kind of packaging machine specialized in processing edible oils, engine oils, lubricants, and many other liquid products for filling. It is engineered mainly for reliability and speed so that it accomplishes dispensing volume and waste configuration, thus turning up productivity at maximum levels. The machine would have PLC controls, servo-driven movements, and drip-free nozzles to provide smooth operation with consistent functioning performance. Being made using high-grade stainless steel, the machine possesses a robust and hygiene-proof structure complying with the industry’s standards such as GMP and FDA. The machine covers a comprehensive range of different shapes and sizes of containers, giving it versatility to suit any production requirement. Automatic Oil Filling Machines are best suited to such industries as food processing, automotive, and cosmetics employing highly efficient production processes with minimal human efforts. With options for additional multi-head filling systems and complete integration with capping and labeling machines, they make an almost complete solution for total automation of production lines. An Automatic Oil Filling Machine is profitability and efficiency for operation, product quality, and the needs of ever-increasing modern demand. This is an ideal choice for any growing business trying to find something reliable, scalable, and cost-effective in oil packaging.

Automatic Ink filling Machine

The Automatic Ink Filling Machine is one machine that is highly specialized in filling inks into bottles, cartridges, and other forms of containers used for printing purposes. The machine is intended to give that precise and speedy dispense on the volumes so waste and productivity could be improved. For the packaging of inks used in printers, markers, or any other applications, it guarantees filling processes that are extremely clean and mess-free. With features such as PLC control, servo-driven components, and adjustable filling nozzles, the Automatic Ink Filling Machine is equipped to handle inks with varying viscosities such as thinner liquids as well as heavier formulations. Its structure sees very tough and much sanitized production and industry conditions such as GMP and FDA guidelines that keep the ink free from any contaminants in the whole process. This is ideal for extremely high quantities with rapid filling, high reliability with minimal downtimes, and high hygiene. It very simple interfaces and maintenance makes it very user-friendly from this point of view. Furthermore, with an Automatic Ink Filling Machine, manufacturers could streamline their packaging works, enhance efficiency, and cut down on labor costs while maintaining the high quality standards of ink packaged. This is the perfect machine for the business looking to do on precision, speed, and sheer reliability in their ink filling processes.

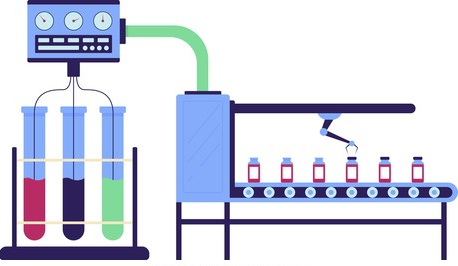

Automatic Syrup Filling Machine

Automatic Syrup Filler Machine is an advanced technology, which is used precisely fills syrup into bottles, jars and different containers. It basically controls volume dispensing accuracy and human errors, and results in reducing wastage of products. Different types of viscosity can be hydrated, and these machines are especially ideal for restaurants, pharmaceuticals, and beverage industries. Precision and hygiene are the most important in any industry. It is universally usable, with PLC control, servo-drive, and adjustable nozzles, customized for any container size and including the fully automatic syrup filling machine. The construction is of high standard, usually in stainless steel, hence durability and compliance with GMP and FDA, therefore no contamination of syrup during filling. Its speed capacities are high with minimum downtime; hence can deal with mass production. It can also be optimally linked with drip-proof nozzles plus in-line capping and labeling systems to be a complete automated packaging solution. By adopting an Automatic Syrup Filling Machine for their production line, businesses streamline processes and enhance operational efficiency while ensuring a quality product. It is a must-have implement for companies going with the market while delivering product integrity and compliance with standards.