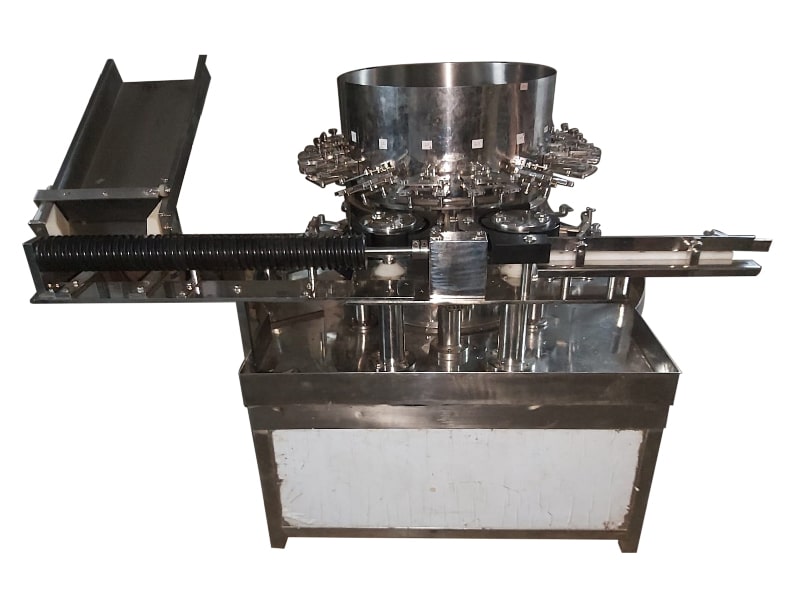

Operation

Ampoules feed from the Infeed tray are received on an Infeed Feed worm then moves on Infeed Star Wheel. The Grippers picks up the Ampoules from Infeed Star Wheel and invert it in neck down position over washing needles and move along with the needle bar for Washing. On completion of a cycle, washed ampoules are again inverted to neck upward position and feed to output star wheel. Washed ampoules received from output star wheel can be collected on Output Tray or can be pushed to tunnel.

Washing Cycle

| 1st Wash | Recycled Water (WFI) |

| 2st Wash | Compressed Air |

| 3st Wash | DM Water |

| 4st Wash | Compressed Air |

| 5st Wash | Water for Injection (WFI Water) |

| 6st Wash | Compressed Air |

Salient Features

- All Contact parts made out from SS 316.

- Entire frame covers & non Contact parts made out from SS 304.

- All finishes, welding joints are processed, treated & equipment selected in accordance with cGMP standards.

- Suitable for 2ml to 100ml vials.

- Low Water Consumption.

- Quick Change over of parts for other size of Vial.

- 3 Pumps and 3 Tanks of 25 liters Each.

- Washing sequence can be made as per customer’s requirements.

Technical Specification

| Model | DRVW-120 | DRVW-240 |

| Output | 70 to 120 Vials/Minute | 90 to 240 Vials/Minute |

| Vial Diameter | 14mm to 56mm | 14mm to 56mm |

| Vial Height | 32mm to 110mm | 32mm to 110mm |

| Power Specification | 4 HP, 3 Phase 50 Hz, 4 wire system | 4 HP, 3 Phase 50 Hz, 4 wire system |

| Optional Accessories | PLC with HMI Aluminum Profile Cabinet covering full machine | PLC with HMI Aluminum Profile Cabinet covering full machine |

| Utility | Air – 20 CFM Water – 200 to 500 Liter/Hour depend upon Ampoule size | Air – 20 CFM Water – 200 to 500 Liter/Hour depend upon Ampoule size |

| Water Tank & Pump | 3 Nos. each with 25 Liters Capacity & Centrifugal Pump | 3 Nos. each with 25 Liters Capacity & Centrifugal Pump |

| Overall Dimension | 2050mm L X 2000mm W X 1210mm H | 2450mm L X 2000mm W X 1300mm H |